+880 1844018235

+880 1844018235

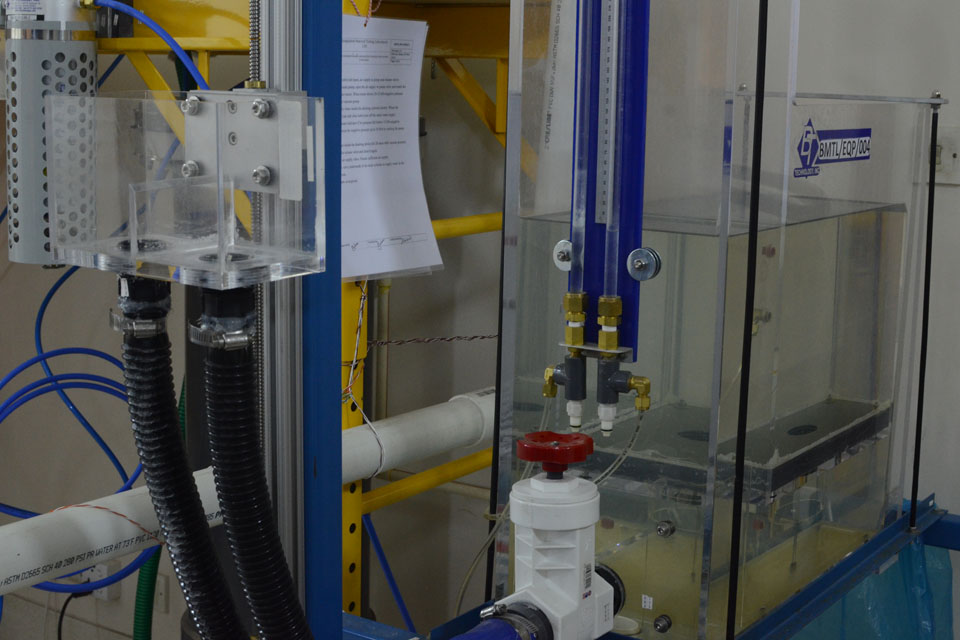

An ISO/IEC 17025 accredited material testing laboratory, a first time venture in Bangladesh

We are specialized in testing construction materials used in large infrastructure projects. Ensuring quality of construction material is crucial for the functionality, safety and durability of the structure. BMTL is committed to provide testing facility in the sector of Civil Engineering especially to Geotechnical, Geosynthetics, Structures and related Materials. BMTL continue to uphold Integrity, Privacy and to achieve Quality Assurance of highest level.

BMTL ensures test results traceable to ISO reference parameters. It offers Independent, Efficient and Cost Effective testing services.

Updated on: 7 February 2023

|

Code No |

Name of Test |

Test Method |

Rate | ||

| USD | EUR | BDT | |||

| Geotextile | |||||

| Non-woven Geotextile Test | |||||

|

GS01 |

Mass Per Unit Area |

ISO 9864 ASTM D5261-10 |

23 |

22 |

1,800 |

|

GS02 |

Thickness at Specified Pressure (2kpa) |

ISO 9863-1 ASTM D5199-12 |

14 |

13 |

1,100 |

|

GS03 |

Wide-Width Tensile Test/Strip Tensile Test |

ISO 10319 ASTM D4595 |

56 |

53 |

4,500 |

|

GS04 |

Static Puncture Test (CBR Test) |

ISO 12236 ASTM D6241 |

38 |

36 |

3,000 |

|

GS05 |

Permeability Test (50mm Head) |

ISO 11058 ASTM D4491 |

53 |

50 |

4,250 |

|

GS06 |

|

ISO 12956 |

250 |

238 |

20,000 |

|

ASTM D4751 |

53 |

50 |

4,250 |

||

|

GS07 |

UV Resistance Test (Fluroscence) |

BS 12224 |

1,250 |

1189 |

100,000 |

|

GS08 |

UV ResistanceTest (Xenon Arc) |

ASTM D4355 |

1,563 |

1487 |

125,000 |

|

GS09 |

Abrasion Test (BAW) |

BAW Guideline ISO 22182 |

2,500 |

2378 |

200,000 |

|

GS10 |

Grab Tensile Test (Strength & Elongation) |

ASTM D4632 |

53 |

50 |

4,250 |

|

GS11 |

Determination of polymeric light stabilizer in polypropylene |

BMTL/Analytical/SOP/001 (Ref: W. Freitag Method-1983) |

1,563 |

1487 |

125,000 |

|

GS12 |

Seam/Joint Strength Test by WideWidth Strip Method |

BDS ISO 10321 |

53 |

50 |

4,250 |

|

GS13 |

Trapezoidal Tear Strength Test |

ASTM D4533-04 |

53 |

50 |

4,250 |

|

GS14 |

Determination of Polyester Staple Fiber Content in Geotextiles/ PP /PSF / Composition Test |

ISO 1833-16 |

69 |

66 |

5,500 |

|

GS15 |

Index Puncture Resistance of Geomembrane and Related Products |

ASTM D4632 |

106 |

101 |

8,500 |

|

GS16 |

Determination of Tensile Properties of Yarns |

ASTM D2256 |

53 |

50 |

4,250 |

|

GS17 |

Standard Test Method for width of Textile Fabric |

ASTM D3774-18 |

56 |

53 |

4,500 |

|

GS18 |

Standard Test Method for Bursting Strength of Textile |

ASTM D3787-16 |

38 |

36 |

3,000 |

|

GS19 |

Determining the Resistance to Acid and Alkaline Liquids (Geotextiles and Geotextile-Related Products - Screening Test Method) (ISO/TR 12960:1998, Modified) |

BS EN 14030 |

375 |

357 |

30,000 |

|

GS20 |

Screening Test Method (Geotextiles and Geotextile-Related Products) |

BS EN 12447 |

313 |

298 |

25,000 |

|

GS21 |

Geosynthetics — Screening test method for determining the resistance of geotextiles and geotextile-related products to oxidation |

ISO 13438:2018 |

2,500 |

2,330 |

2,00000 |

| Woven Geotextile Test | |||||

|

GS21 |

Determination of Mass Per Unit Area |

ISO 9864 ASTM D5261 |

23 |

22 |

1,800 |

|

GS22 |

Determination of Thickness at Specified Pressures |

ISO 9863-1 ASTM D5199 |

14 |

13 |

1,100 |

|

GS23 |

Tensile strength and Elongation |

ISO 10319 ASTM D4595 |

56 |

53 |

4,500 |

|

GS24 |

Grab Strength (Grab Breaking Load) and Elongation |

ASTM D4632 |

53 |

50 |

4,250 |

|

GS25 |

CBR Puncture Test (Static) |

ISO 12236 ASTM D6241 |

38 |

36 |

3,000 |

|

GS26 |

Trapezoid Tearing Strength of Woven Geotextiles |

ASTM D4533 |

53 |

50 |

4,250 |

|

GS27 |

Apparent Opening Size of Geotextile |

ASTM D4751 |

53 |

50 |

4,250 |

|

GS28 |

Permittivity of Geotextile |

ASTM D4491 |

53 |

50 |

4,250 |

|

GS29 |

Permeability of Geotextile |

ASTM D4491 |

53 |

50 |

4,250 |

|

GS30 |

Hydraulic Transmissivity of Geosynthetic Materials |

ASTM D4716 |

53 |

50 |

4,250 |

|

GS31 |

Index Puncture Resistance of Geomembrane and Related Products |

ASTM D4833 |

106 |

101 |

8,500 |

| Fiber Test | |||||

|

FR01 |

Density |

BMTL/Fiber/SOP/001 (Ref:Archimede's Principle) |

13 |

12 |

1,000 |

|

FR02 |

Melting Point |

BMTL/SOP-MP/0025 |

19 |

18 |

1,500 |

|

FR03 |

Denier |

ASTM D1577-07 |

32 |

30 |

2,500 |

|

FR04 |

Length |

ISO 6989 |

13 |

12 |

1,000 |

|

FR05 |

Determination of breaking force and elongation at break of individual fibres |

ISO 5079 |

60 |

57 |

4,800 |

|

FR06 |

Crimp |

ASTM D3937-12 |

13 |

12 |

1,000 |

| Aggregate | |||||

|

AG01 |

Sieve analysis/ Gradation /FM of CA |

ASTM C136 |

78 |

74 |

6,200 |

|

AG02 |

Sieve Analysis/ Gradation of Base/Sub- Base |

ASTM C136 |

126 |

120 |

10,000 |

|

AG03 |

Sieve Analysis/ Gradation/ FM of Ballast |

ASTM C136 |

103 |

98 |

8,200 |

|

AG04 |

Sieve analysis & FM of FA |

ASTM C136 |

44 |

42 |

3,500 |

|

AG05 |

% Finer than # 200 sieve/ Fine content/Silt content |

ASTM C117 |

45 |

43 |

3,550 |

|

AG06 |

Soundness of Aggregate (Na2SO4/ MgSO4) |

ASTM C88 |

252 |

240 |

20,000 |

|

AG07 |

Elongation Index (EI) / Shape Test |

BS 812 (Part-1) |

98 |

93 |

7,830 |

|

AG08 |

Flakiness Index (FI) |

BS 812 (Part-1) |

90 |

86 |

7,200 |

|

AG09 |

L.A. Abrasion of CA |

ASTM C131 |

91 |

87 |

7,250 |

|

AG10 |

L.A. Abrasion of Ballast |

ASTM C535 |

94 |

89 |

7,500 |

|

AG11 |

Unit weight of aggregate of CA |

ASTM C29 |

57 |

54 |

4,500 |

|

AG12 |

Unit weight of aggregate of FA |

ASTM C29 |

50 |

48 |

4,000 |

|

AG13 |

Absorption and Specific Gravity of CA |

ASTM C127 |

81 |

77 |

6,400 |

|

AG14 |

Absorption and Specific Gravity of FA |

ASTM C128 |

75 |

71 |

6,000 |

|

AG15 |

Absorption of CA/ FA |

ASTM C127 |

50 |

48 |

4,000 |

|

AG16 |

Aggregate Crushing Value (ACV) / Compress Strength |

BS 812 (Part-3) |

90 |

86 |

7,200 |

|

AG17 |

Aggregate Impact Value (AIV) |

BS 812 (Part-3) |

64 |

61 |

5,130 |

|

AG18 |

Ten Percent Fine Value (TPV) |

BS 812-111 |

129 |

123 |

10,350 |

|

AG19 |

Clay Lumps & Friable Particles |

ASTM C142 |

64 |

61 |

5,130 |

| Bitumen/ Asphalt | |||||

|

BT01 |

Penetration of Bituminous Materials |

ASTM D5 |

62 |

59 |

4,900 |

|

BT02 |

Flash and Fire Points of Bituminous Materials/ Petroleum Products by Cleveland Open Cup Tester |

ASTM D92 |

62 |

59 |

4,900 |

|

BT03 |

Solubility of Asphalt Materials in Trichloroethylene |

ASTM D2042 |

60 |

57 |

4,750 |

|

BT04 |

Ductility of Asphalt Materials |

ASTM D113 |

60 |

57 |

4,750 |

|

BT05 |

Softening Point of Bitumen (Ring-and-Ball Apparatus) |

ASTM D36 |

60 |

57 |

4,750 |

|

BT06 |

Specific gravity of Bituminous Materials |

ASTM D70 |

62 |

59 |

4,900 |

| Bricks | |||||

|

BR01 |

Absorption |

ASTM C67 |

28 |

26 |

2,200 |

|

BR02 |

Crushing strength |

ASTM C67 |

56 |

53 |

4,500 |

|

BR03 |

Size & shape |

ASTM C67 |

37 |

35 |

2,900 |

|

BR04 |

Unit Weight |

ASTM C67 |

50 |

48 |

4,000 |

|

BR05 |

Efflorescence (Need 10 bricks) |

ASTM C67 |

56 |

53 |

4,500 |

|

BR06 |

Flexural Strength |

ASTM C67 |

88 |

84 |

7,000 |

| Cement | |||||

|

CE01 |

Compressive Strength of Hydraulic Cement (Mortars made with Ottowa sand) |

ASTM C109 |

126 |

120 |

10,000 |

|

CE02 |

Specific gravity/ Density of Hydraulic Cement |

ASTM C188 |

50 |

48 |

4,000 |

|

CE03 |

Fineness of Hydraulic Cemente |

ASTM C204 |

37 |

35 |

2,900 |

|

CE04 |

Normal Consistency of Hydraulic Cement Paste |

ASTM C187 |

35 |

33 |

2,750 |

|

CE05 |

Setting time of Hydraulic Cement Paste |

ASTM C191 |

50 |

48 |

4,000 |

|

CE06 |

Weight of cement bag |

BMTL/SOP/CE/006 |

9.5 |

9 |

750 |

| Concrete | |||||

|

CC01 |

Concrete cylinders (100mm X 200 mm), for a set of 3 cylinder. |

ASTM C39 |

25 |

24 |

2,000 |

| Certification | |||||

|

PC01 |

Product Certification |

Per Product |

250 |

238 |

20,000 |

|

PC02 |

Decision Rule of Testing Standard |

Per Standard |

63 |

60 |

5,000 |

Notes:

* Samples must be delivered to laboratory with proper supporting

documents.

* Minimum 50% advance should be paid to get samples into testing queue.

* Full test value to be paid before receiving the reports

* Reports will be available

at laboratory only.

The laboratory is ISO/IEC 17025 certified and in compliance with ISO 9001.

We understand the aspects of quality management that are key to increased productivity – customer satisfaction, but also increased effectiveness, maximum output and quality control.

At Bangladesh Material Testing Laboratory (BMTL), our Quality Program is the driving force for all of our business operations. BMTL's quality system determines our administrative duties, directs all technical activities, and manages all issues related to sampling and specimen traceability.

Whether you design, manufacture or supply materials, you need to comply with international and regional directives and regulations. We have accreditations to all major standards and regional regulations of material testing.

Quality Assurance and Quality Control form a significant part of the testing that we do at BMTL. We know how important it is for manufacturers and end-users across all industries to ensure quality and performance consistency of materials, components and products in an increasingly competitive global marketplace.

The quality conformity testing that we offer means that you can be sure of the consistency of your materials and products, thereby satisfying regulatory authorities and your own clients. Testing can be done batch-to-batch or at appropriate intervals to ensure consistency.

As BMTL is an independent BAB (Bangladesh Accreditation Board) accredited and trusted testing house, you can be sured that the test data that we provide you with is accurate and reliable. Our highly qualified and experienced technical staff use transparent, traceable, calibrated approaches and state-of-the-art equipment.

Bangladesh Material Testing Laboratory Ltd.

33 & 37 Milk Vita Road

Section 7, Mirpur

Dhaka 1216

Bangladesh.

33 & 37 Milk Vita Road

Section 7, Mirpur

Dhaka 1216

Bangladesh.

+880 1844018235

+880 1844018235